Drones are no longer what you used to know; they have been evolving into becoming fully autonomous tools that can take off, land, recharge and upload data on their own without any human intervention. In 2025, drone docking stations, also known as drone- in-a- box-systems, are coming in at the heart of this transformation.

The global drone docking station market is expected to grow considerably, with the market size projected to hit nearly USD 1.2 billion by 2032 compared to USD 300 million as of 2023, with a strong CAGR of 15%.

For surveyors, GIS professionals, security, town planners and mapping organizations, this innovation has the potential to cut costs, improve safety, and deliver near real-time insights across industries like construction, mining, agriculture, security, traffic monitoring and urban planning.

Table of Contents

What is a Drone Docking Station?

A drone docking station can be described as an automated base designed to support remote operations of drones without the need of on site personnel. Drone docking stations are particularly very useful for beyond visual line of sight operations as they enable seamless deployment and retrieval of drones even across long-range operations.

Through automated operations, the drone – in – a – box system comes with many features such as:

- Precise taking off and landing ( without onsite pilot) through highly accurate GPS positioning or visual markers

- Automatic recharge or swapping of batteries

- Data sync (images or videos), real-time monitoring or feed

- Remote operations (automatic and semi – automatic operation)

- Automated, routine and instant deployment of drones

- Protective enclosure (weatherproof box or shelter)

A drone docking station can be viewed as a charging platform and data management hub for drones. As drone docking stations eliminate manual interventions, they also assist in managing repetitive drone tasks and missions such as inspections, monitoring and data collection, reducing downtime and enhancing operational efficiency.

Applications of Drone Docking in Various Industries

The growing demand for drone docking stations is necessitated by the growing need for automation in drone operations. The adoption of drone technology in industries such as logistics, agriculture, and surveillance will require reliable docking stations that facilitate continuous operations, and this will be a major growth driver for the global drone docking station market.

- Construction & Infrastructure – Due to the routine and timely nature of some construction and infrastructure monitoring, docking systems can play a critical role in daily progress monitoring through automated flight schedules.

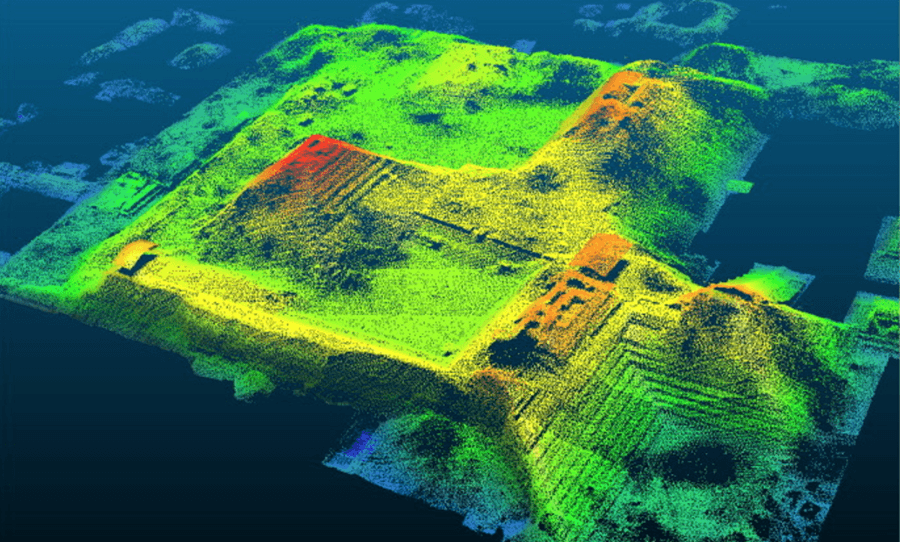

- Mining & Quarrying – helps in monitoring of mining operations, stockpile volume tracking, slope stability analysis, pit and blasting operations. A good example is that in a mining site, a drone with docking can map the pit every 2 hours, providing live volumetric updates for production monitoring.

- Agriculture – can be used in routine crop health analysis, spraying, field monitoring, mapping and pest inspections. In a case study in the attached video, a drone docking system was used in grain handling at a site, including asset inspection, bed scarring and stockpile calculations at a much faster rate than before.

- Urban Planning – From traffic monitoring, emergency response, critical infrastructure monitoring to public safety and many others. Drone docks can be strategically positioned in the city to respond to emergencies, monitor traffic, do routine inspections of public infrastructure like telecoms boosters, traffic lights, street cameras, bridges and overpasses, gas and water lines, electricity power lines and many others.

- Disaster Response & Environmental Monitoring – drone docks enable rapid deployment with minimal human input on disaster response like floods, wildfires, landslides, etc. Environmental monitoring of hazardous and life-threatening scenarios like volcanoes, inspection in dangerous environments etc can be easily enabled by drone docks.

- Security and Surveillance – Continuous operation of security and surveillance, as they can recharge and resume their flights with minimum human intervention and reduced or zero downtime. This has become very much applicable in security and surveillance scenarios such as border patrols, large events, constant monitoring of facilities and infrastructure e.g mines, neighbourhoods, business and industrial premises.

Here Are Some Drone Docking Solutions

A recent study by Cognitive Market Research highlights the main factors influencing the Drone Docking Station market within the aerospace and defense sector. The findings indicate that although key market factors are fostering growth, the sector also encounters challenges such as increased R&D expenses, strict regulations, supply chain weaknesses, and variable defense budgets.

Here are some of the best drone docking stations in 2025:

DJI Dock 2 & 3

DJI Docks are extremely rugged, reliable, and made to run 24/7, rain or shine, day or night. Each DJI Dock will contain a Matrice 30 that lands, recharges, takes off, and performs missions programmed in DJI FlightHub 2.

The DJI Matrice 30 Dock system comes with super-fast charge and cooling functionality, charging the drone from 10 – 90% in 25 minutes. It also comes with the DJI Flighthub 2 software that allows for full unlocking of its functionality from the cloud i.e creating, scheduling and editing missions including managing the collected data.

The DJI Dock 2 & 3 is a robust, affordable, quick deployment, and scalable solution that leads and if often preferred in the market.

XRTech Group Drone in a Box Solutions for DJI M300 & M350

The XRT Battery Drone in a Box Solution Swap Dock for DJI Matrice 350 RTK Series works with both the DJI Matrice 350 RTK and the DJI Matrice 300 RTK. When used with the XRT Cloud Box M2, it lets you connect to 5G, control it from a distance, send data in real time, and hop between multiple points.

This DJI drone battery charging station cuts down on downtime by automatically changing out drone batteries in less than three minutes. Perfect for important tasks that need drones to fly missions all the time without any help from people.

The Hextronics Atlas

The Hextronics Atlas is a high-quality docking station for DJI Matrice 300 and 350 RTK drones. It lets you keep working by letting you swap out batteries every 90 seconds, store 8 batteries, and change the way the batteries are set up. Its tough design can handle extreme conditions and support advanced payloads for public safety, agriculture, and infrastructure inspection.

OmniDock Standard

The first drone-independent docking station designed for multi-UAV operations is the OmniDock Standard. It can hold one large drone or two smaller ones and has a hemispheric, windproof design. It blends in perfectly with autonomous workflows for a variety of industries thanks to its quick actuation, modular configurations, and HVAC-controlled dependability.

Drone Dock Challenges & Considerations

- Cost – docking systems are still expensive, ranging from US$20k to US$60k

- Regulations – BVLOS operations often require special approvals depending on the country and local governing aviation laws and regulations.

- Connectivity – remote sites need stable internet/cloud integration, which is often a challenge in most of the areas of drone operations or where drone docks would be much needed.

- Maintenance– docking systems themselves need upkeep and maintenance for proper and safe running. It involves regular checks and cleaning on the physical and software components of the system and also ensuring that a stable operating environment and temperature are maintained for a safe running of the system.

- Employment Shift – just like every automation and now the coming in of artificial intelligence (AI), drone docks pose a threat to some current employment prospects for drone professionals like drone pilots but can also open more opportunities in other spaces like maintenance, data analysis and interpretation, programming and streamlining drone operations workflows.

The Future of Drone Docking In The Next 5 Years

Within the next 5 years, we can expect the drone docking system adoption to pick up among many other trends such as:

- Wider adoption in Africa and other emerging markets as the cost of acquiring and maintenance drops.

- Integration with AI-powered flight management and data analytics.

- Solar-powered docking stations for off-grid and remote operations.

- Integration with various payloads and different drone models for a wider adoption of the systems in different industries.

For drone operators, embracing drone docking isn’t just about convenience — it’s about unpacking a new level of efficiency, competitiveness, and data-driven decision making.

Drone docking stations aren’t just cool new things; they’re the next step in how drones will be used.

Drone operators who use drone-in-a-box systems early will have a big advantage over their competitors as costs go down and rules catch up.

Whether in construction, mining, agriculture, security or urban monitoring, automated drone operations are set to reshape drone operations workflows in 2025 and beyond.

Are you exploring automated drone operations? Subscribe to Geomatics Central for the latest drone technology updates, tutorials, and case studies.